IMW institute

Laboratory for Non-Destructive Testing

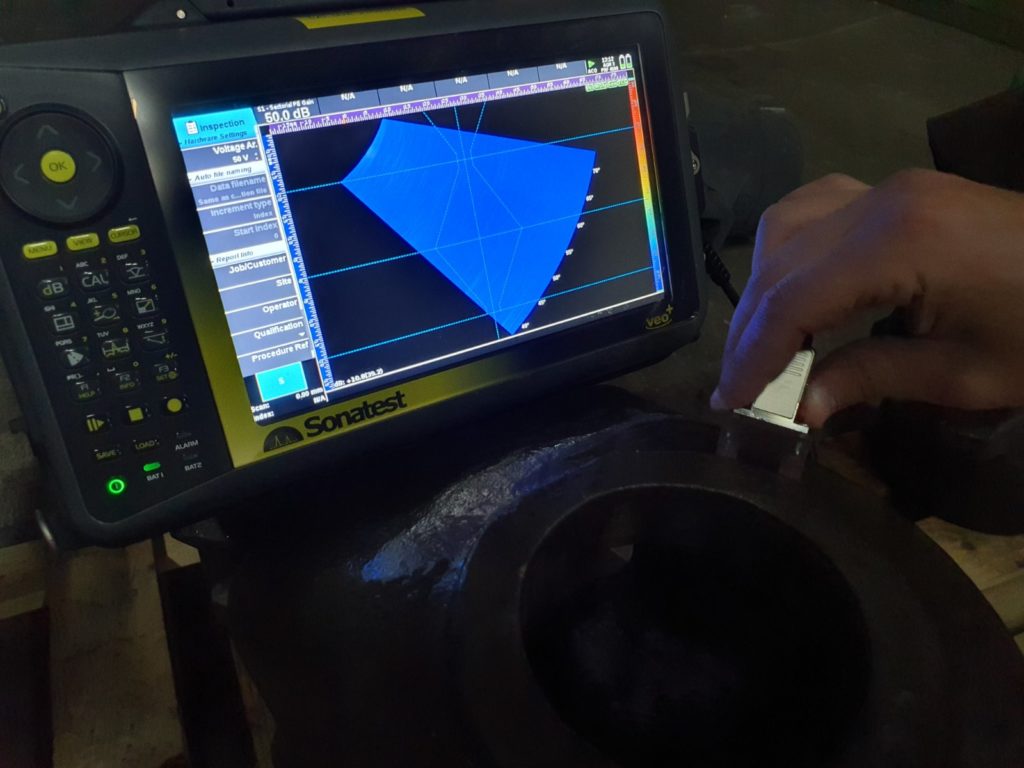

Ultrasonic Testing of Metals and Welded Joints (UT)

- The Sonatest VEO+ Ultrasonic Device is a state-of-the-art instrument for detecting volumetric defects in metal parts and welded joints. It is also used for crack detection, corrosion mapping, aerospace testing, and composite inspection.

- Testing is conducted using four methods:

- Conventional

- Phased Array

- TOFD

- FMC/TFM

- The laboratory has over 60 probes, enabling a wide range of testing capabilities.

Ultrasonic Device M2M Gekko

state-of-the-art phased array flaw detector. It provides built-in real-time TFM, as well as phased array beamforming technologies and conventional UT technology, all through a modern and intuitive software interface . In the field, it is a proven flaw detector that offers PAUT, UT, TOFD and TFM via the streamlined Capture™ user interface. It is available in 32:128, 64:64 or 64:128 channel configurations, and M2M Gekko combines high resolution and speed while reducing inspector training time.

- Examinations are carried out through 4 methods:

- Conventional

- PAUT (Phased Array Method)

- TOFD (Time of Flight Diffraction)

- FMC (Full Matrix Capture)

- TFM (Total Focusing Method)

Digital Radiography Testing

Teledyne ICM CP300D System

- CP300D Generator (30–300 kV, 1–10 mA)

- Detector (154 microns, detector dimensions: 464×388 mm)

- Sherlock NDT software

- Duplex IQI D13 Wire Penetrometers for Aluminum (1Al, 6Al, 10Al, and 13Al)

- Wire Penetrometers for Steel (1Fe, 6Fe, 10Fe, 13Fe)

Digital Radiography – Teledyne ICM CP300D System

We present a high-end solution for digital industrial radiography, combining the Teledyne ICM CP300D generator, a high-resolution detector, and advanced Sherlock NDT software – ideal for precise and efficient inspection in NDT applications.

Main Features:

CP300D Generator (30–300 kV, 1–10 mA)

A high-voltage digital generator with a wide range of voltage and current, allowing flexible use in various industrial applications. Stable operation and precise parameter control ensure high-quality imaging.

High-resolution Digital Detector (154 µm)

Panel dimensions: 464 × 388 mm

Enables imaging on a large surface with exceptional detail clarity, ideal for detecting even the smallest irregularities.

Sherlock NDT Software

Intuitive and powerful software for image acquisition, processing, and analysis. Provides efficient data management, automated reporting, and easy defect detection.

Visual Testing (VT)

- Visual testing of metals and welded joints is applied as a basic non-destructive testing method and includes the detection of surface discontinuities and non-compliance of joint geometry with standard requirements.

- It is used both in the production phase and for checking the condition of welded joints on objects in operation.

- The laboratory has complete equipment for such types of testing.

liquid penetrant testing (PT)

- This method involves testing with colored and fluorescent penetrants. This method of testing detects surface discontinuities on metals, non-metals (plastics and ceramics) and on welded joints.

- The test is based on the detection of surface discontinuities larger than 10μm. The method is based on the capillary effect, i.e. the penetrant liquid penetrates the discontinuity and is then drawn to the surface by the developer.

magnetic particle testing (MT)

- This test method detects surface and subsurface discontinuities in ferromagnetic materials.

- The method is applicable for testing both base materials and welded joints.

- The laboratory has the most modern electromagnetic yoke, a white light source and an ultraviolet light source (UV lamp).