IMW Institut

MECHANICAL-METALOGRAPHIC LABORATORY

Mechanical-metalographic laboratory is equipped with state-of-the-art equipment that allows a large range of testing, both mechanical and microstructural characteristics of metallic materials and welds.

Mechanical-metalographic laboratory

Tensile, bend and pressure testing (shimadzu ag-x)

- Universal testing machine for tightening, pressing and bending. The maximum test force is 300 kN while the range of speeds at which experiments can be performed is from 0.0005 mm / min to 500 mm / min and the load can be set continuously and cyclically. The machine uses specialized TRAPEZIUM X software for mechanical testing.

- The maximum opening of the crosshead with clamping jaws is 450 mm and the dimensions of the sample to be tested are:

- For rectangular cross-section specimens:

W:0-50 mm, T:0-25,5 mm

2. For circular cross-section specimens:

Diameter: 4-30 mm

Mechanical-metalographic laboratory

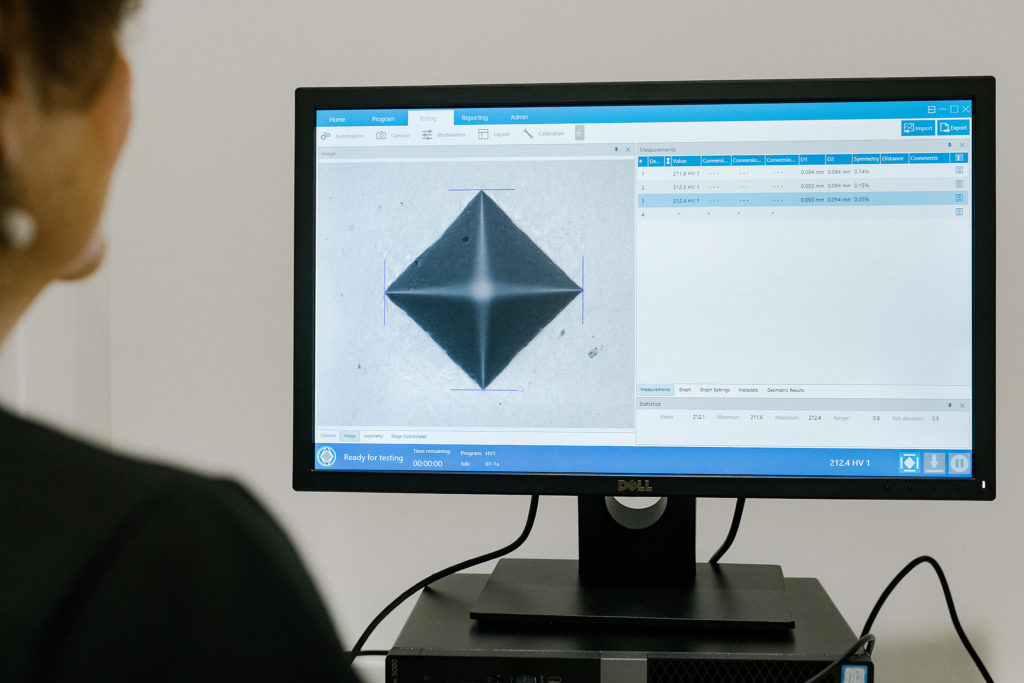

determination of micro and macro hardness of metals and welds

- The laboratory has 4 independent devices for determining micro and macro hardness according to Brinell and Vikers:

- Willson VH1150 i VH1102 machines for testing of macro and micro hardness of materials according to Vikers. The load range these machines can handle are from 0.3 kgf to 50 kgf or 0.01 kgf to 2 kgf. Sample height up to 210 mm and width up to 160 mm for macro and height 130 mm and width 130 mm for micro tests.

- Hardness tester Echo LAB HB 625 Z is a Brinell material hardness testing machine. With the test forces range from 49.03 N (5 kg) to 612.9 N (62.5 kg). Hardness testing ranges from 8 to 650 HBW. Sample height up to 170 mm and width up to 130 mm.

- Wilson BH3000is a Brinell material hardness testing machine. The load range this machine can set is from 62.5 kgf to 3000 kgf. Sample height up to 280 mm and width up to 130 mm.